Shrinkage and swelling behavior of clayey soils pose an interesting engineering challenge. Landfill liner and cover systems consist of a barrier provided by the clayey soil. This barrier curtails the movement of leachate at the bottom and the gases on the top. When the cover systems are subjected to rainfall and then drying, these systems swell and shrink a lot. This alternate wetting and drying cycle produces cracks in the cover system. Once these cracks pass the cover/liner system, they ‘short-circuit’ the effluents and cause release of leachate to the ground water and landfill gases to the atmosphere. With Prof Ayothiraman, I started to look for different alternatives to increase the tensile strength of the soil and arrest the development of the these tensile cracks.

Shrinkage and swelling behavior of clayey soils pose an interesting engineering challenge. Landfill liner and cover systems consist of a barrier provided by the clayey soil. This barrier curtails the movement of leachate at the bottom and the gases on the top. When the cover systems are subjected to rainfall and then drying, these systems swell and shrink a lot. This alternate wetting and drying cycle produces cracks in the cover system. Once these cracks pass the cover/liner system, they ‘short-circuit’ the effluents and cause release of leachate to the ground water and landfill gases to the atmosphere. With Prof Ayothiraman, I started to look for different alternatives to increase the tensile strength of the soil and arrest the development of the these tensile cracks.

Fiber based reinforcement has been used in wide variety of engineering materials; concrete, composites and soils. These micron size fibers impart tensile strength increasing the strength and durability of the parent materials. Generally, man-made fibers, such as, steel, polypropylene, nylon etc, are used. A sustainable alternative is present on our bodies.

Think about it, What is the most abundant material on a human body (apart from the skin)? Look on your head!

Human hair is viewed as a waste or deleterious substance in most societies, therefore it is thrown in the MSW landfills or thrown down the drain. In areas of huge population (like, Delhi) the hair fibers clog the drainage system, occupy a huge volume in landfills and the nitrogen present in the hair causes eutrophication when they reach a water body. The best possible alternative is to use the waste as a resource. High durability, excellent tensile strength, and lightweight make human hair an ideal material for soil reinforcement, and their low biodegradability and longevity make them a durable material.

A few notable details of the study are presented below:

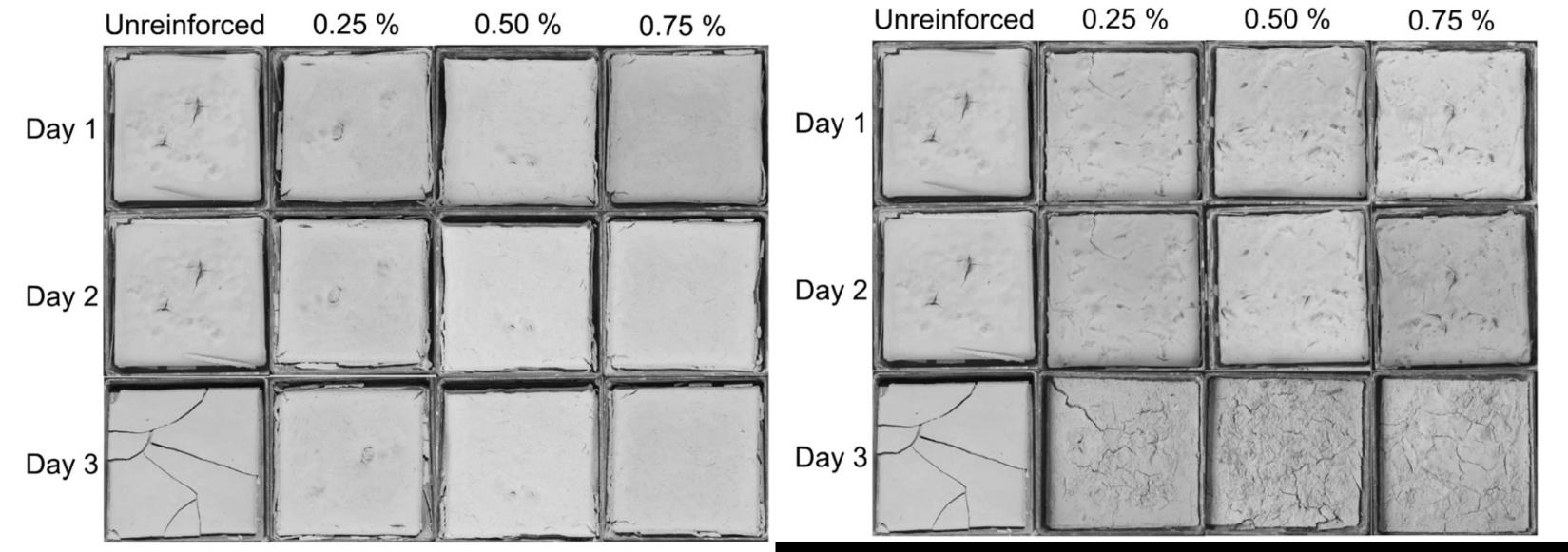

- Experimental study of shrinkage/desiccation was conducted on naturally available clay soil reinforced with polypropylene, coir and human hair fiber.

- Custom steel mold was fabricated and the mixture was kept in the sunlight, during the summer months in Delhi, to capture the natural environmental conditions.

- Photographs of cracks were processed using image processing techniques to get the various crack parameters.

- Human hair fiber provided similar response as the polypropylene hair fiber, therefore, synthetic fibers can be replaced with natural alternatives.

This study is